No Product In Inquiry List

Deltatec 90N Marketing Kit Boehlerit

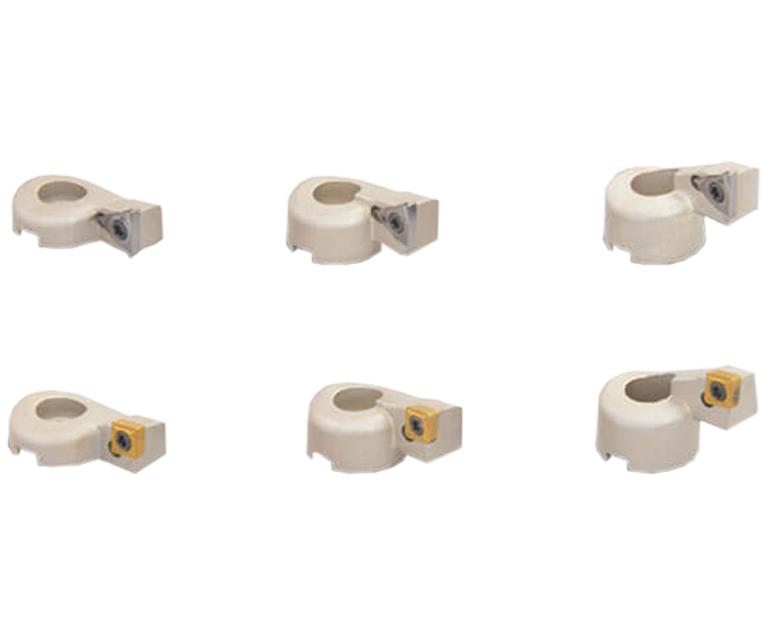

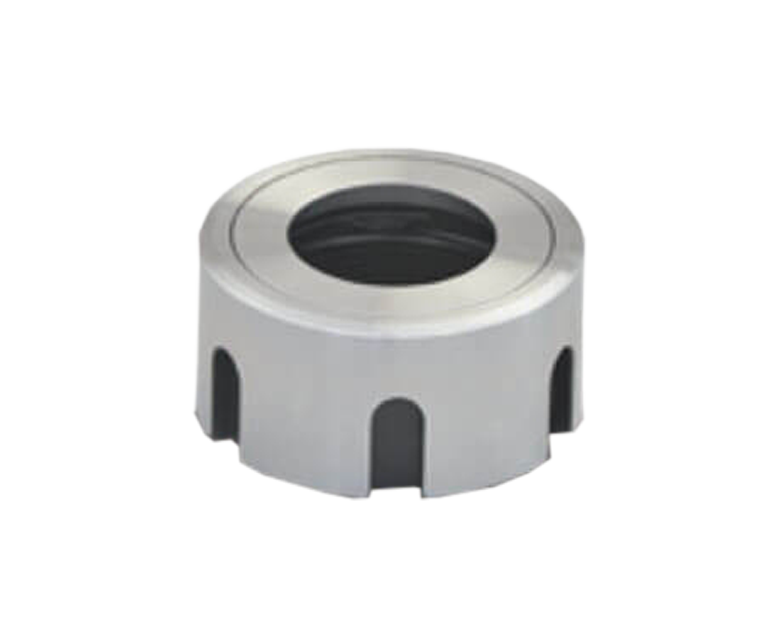

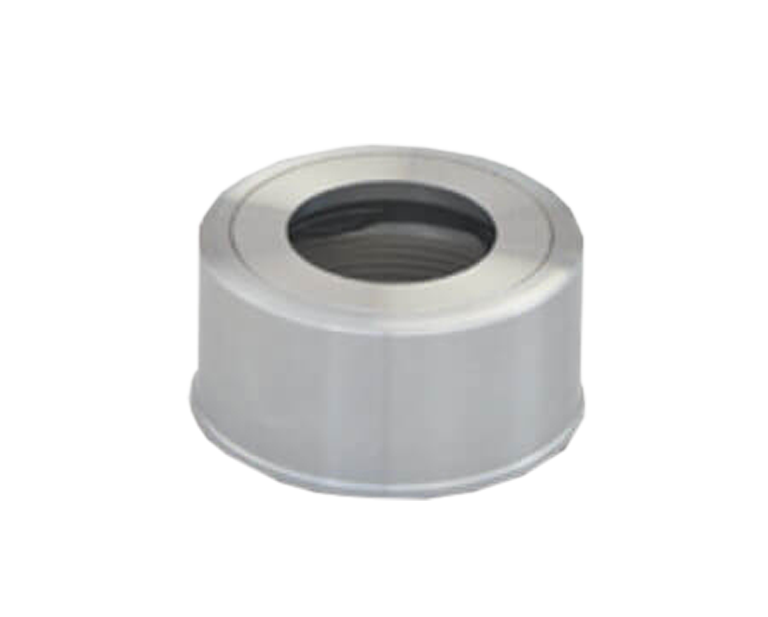

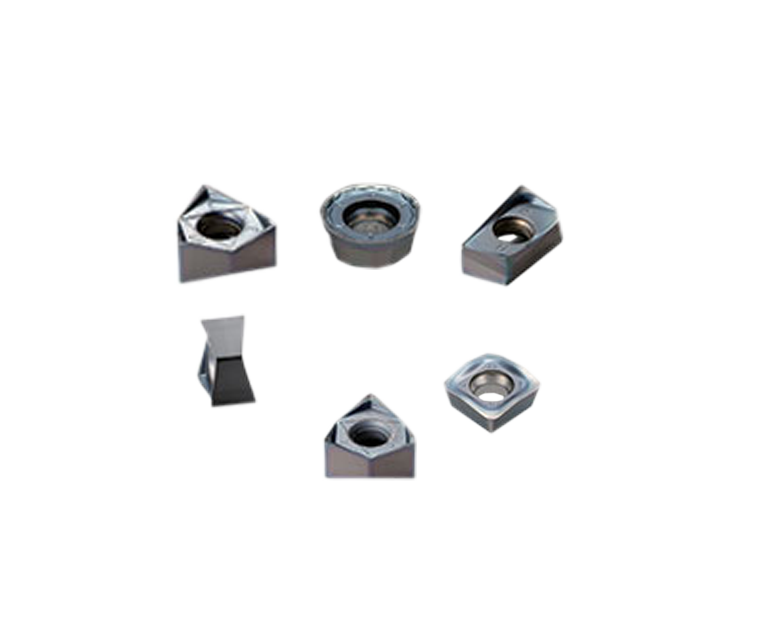

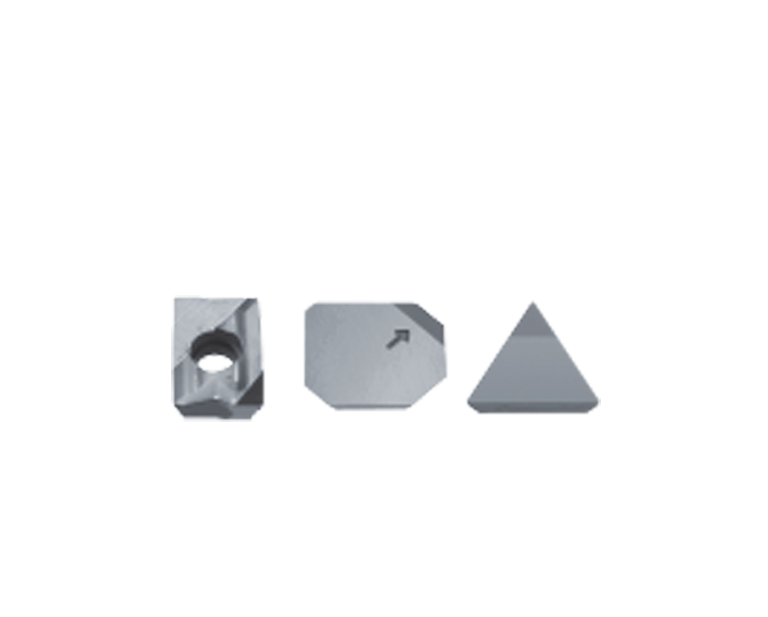

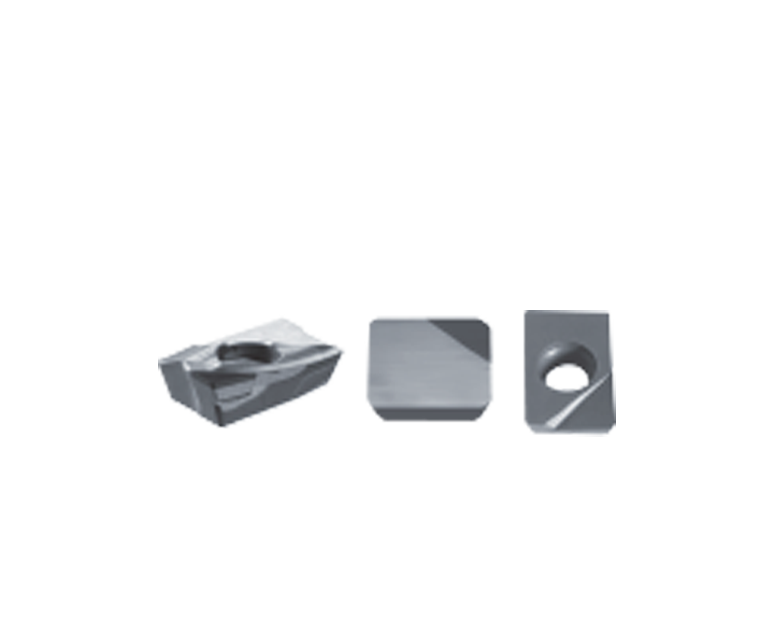

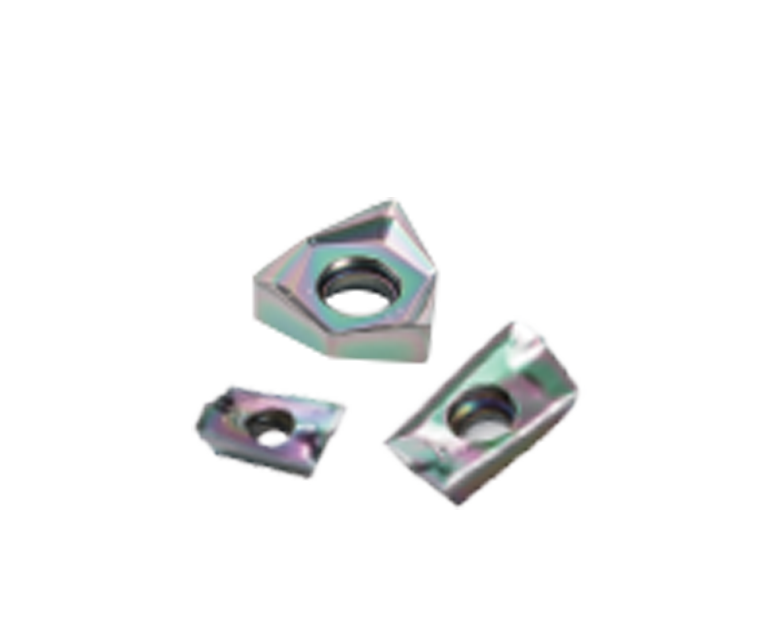

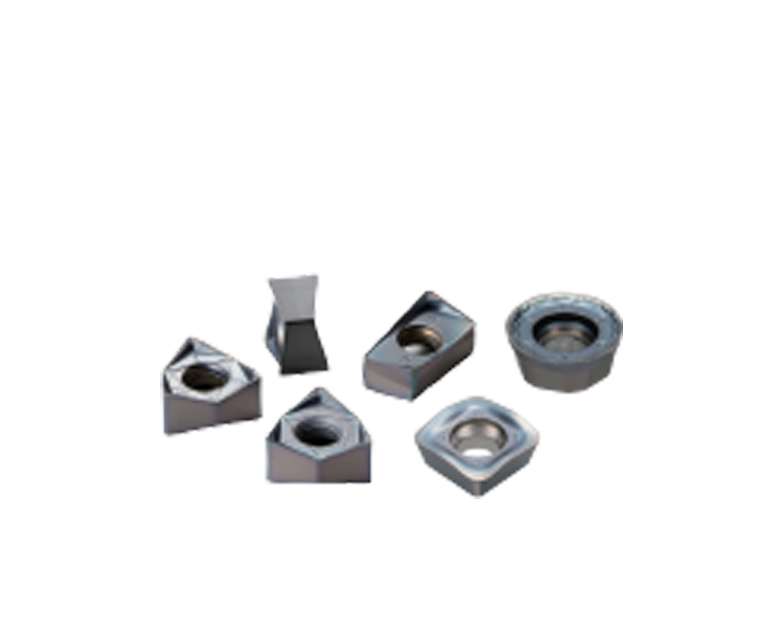

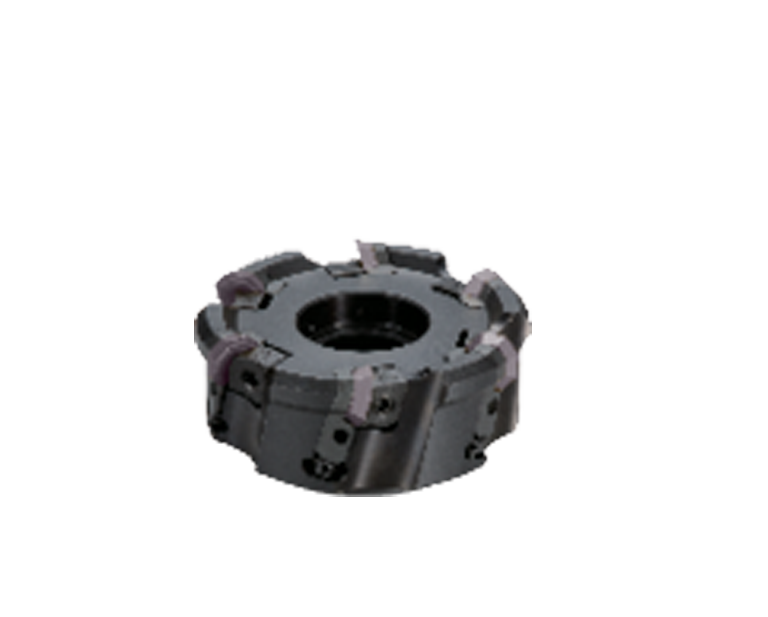

The Boehlerit milling range also includes a tool system with a tangential clamping system for cutting inserts.

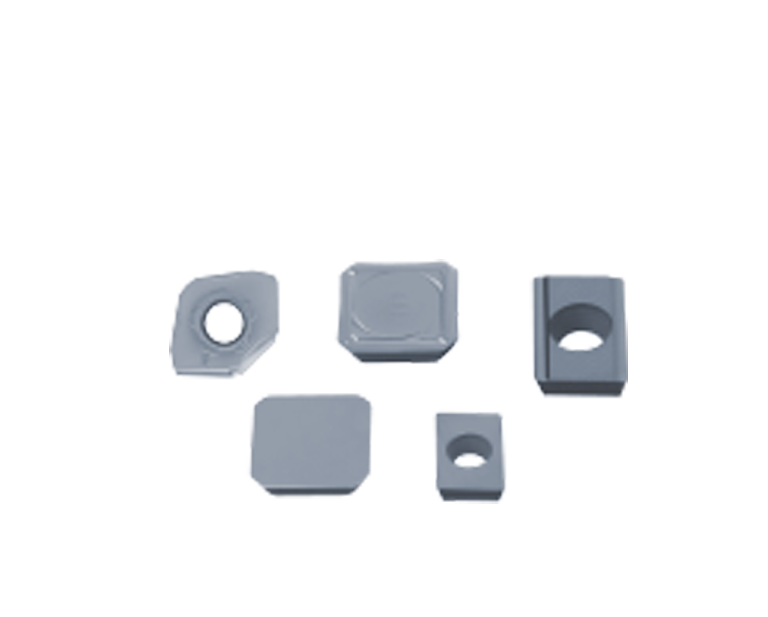

The 90° edge milling system DELTAtec 90N Tang is ideal for the roughing of steel and cast materials and

combines a smooth cutting motion with extremely stable machining characteristics. With 4-bladed cutting

inserts, the system ensures a high level of productivity while keeping tooling costs low.

Deltatec 90N Marketing Kit Boehlerit

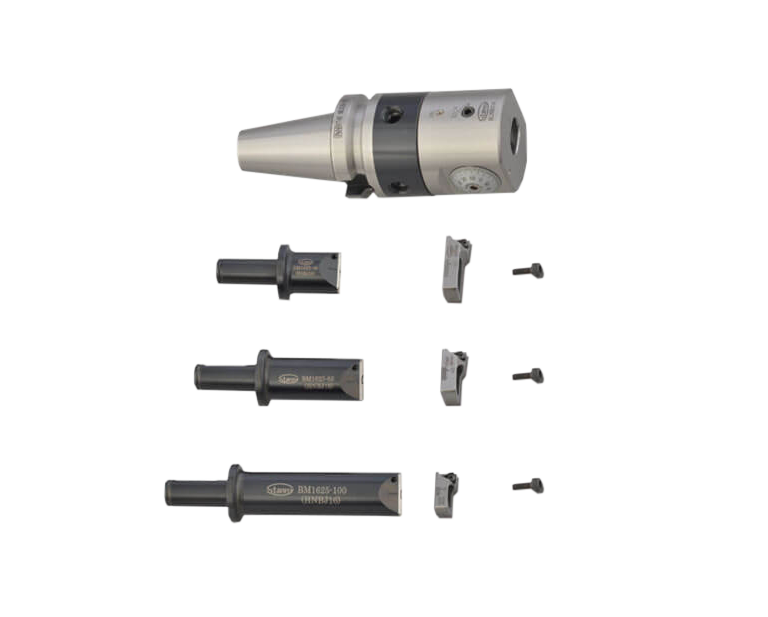

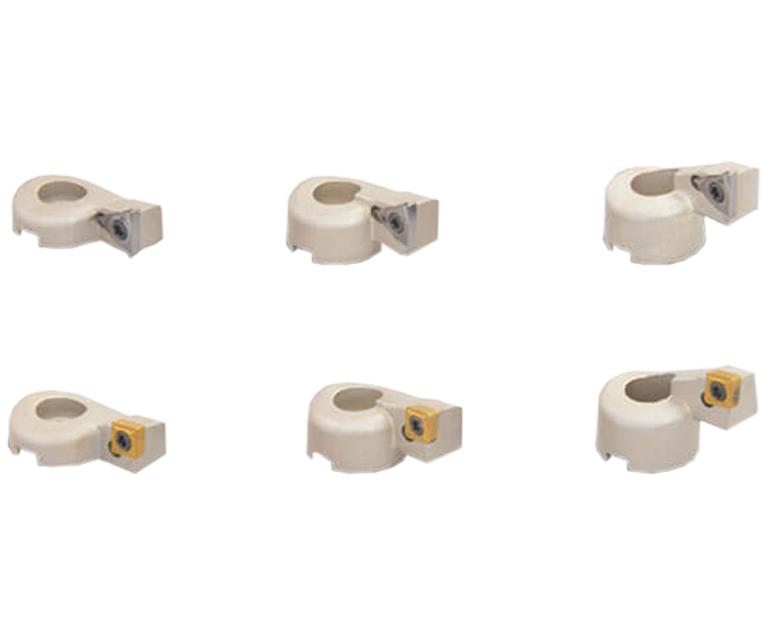

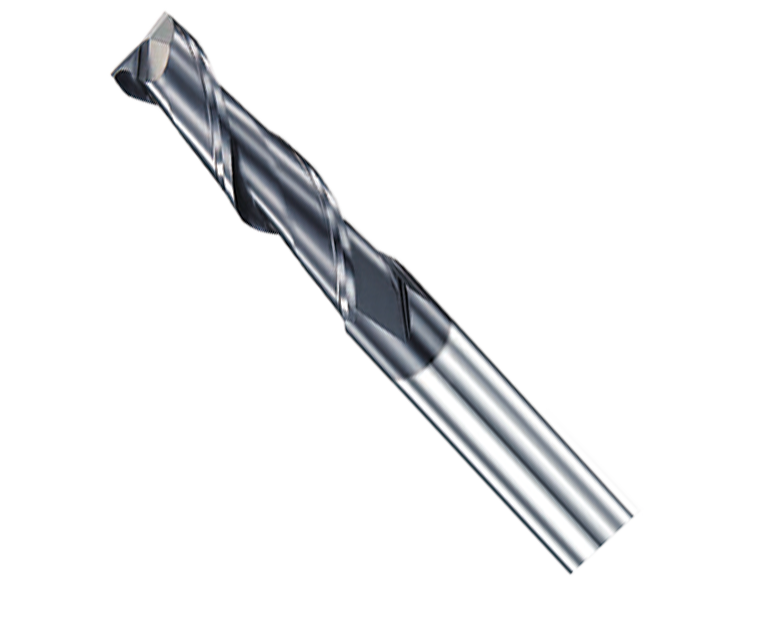

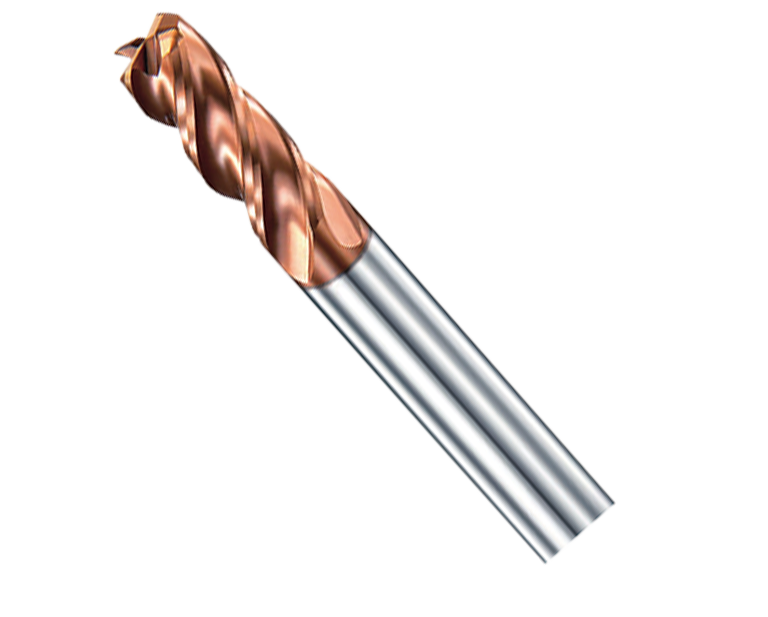

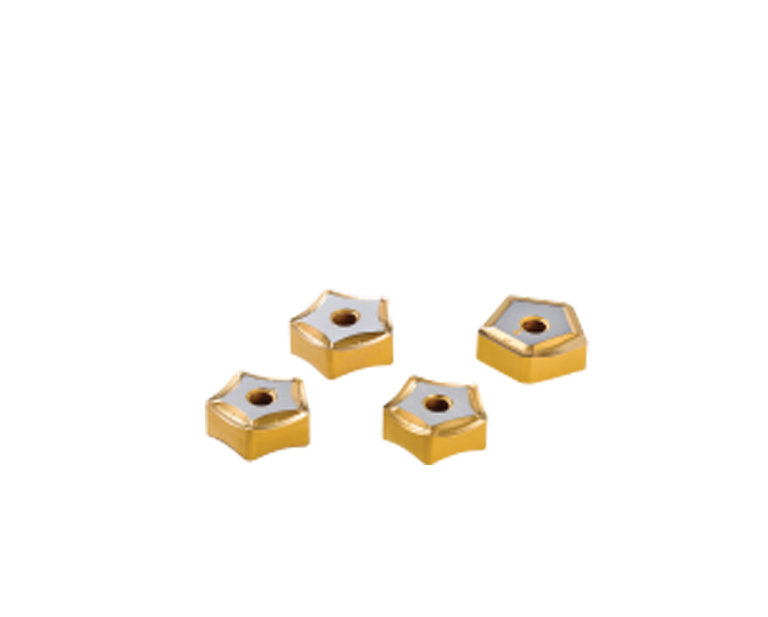

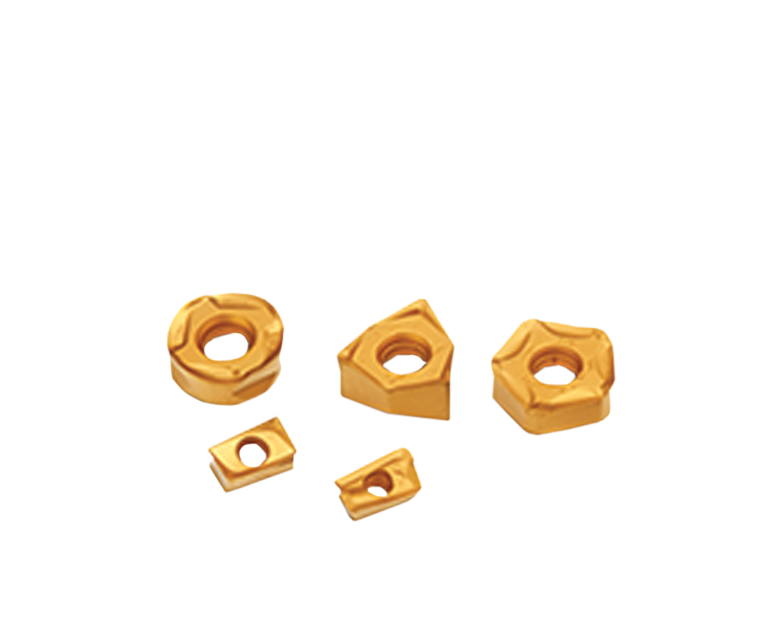

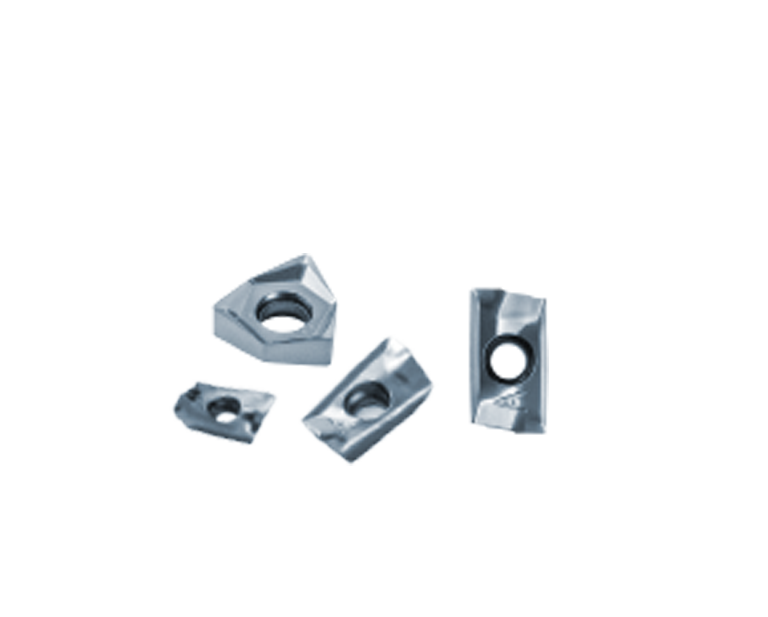

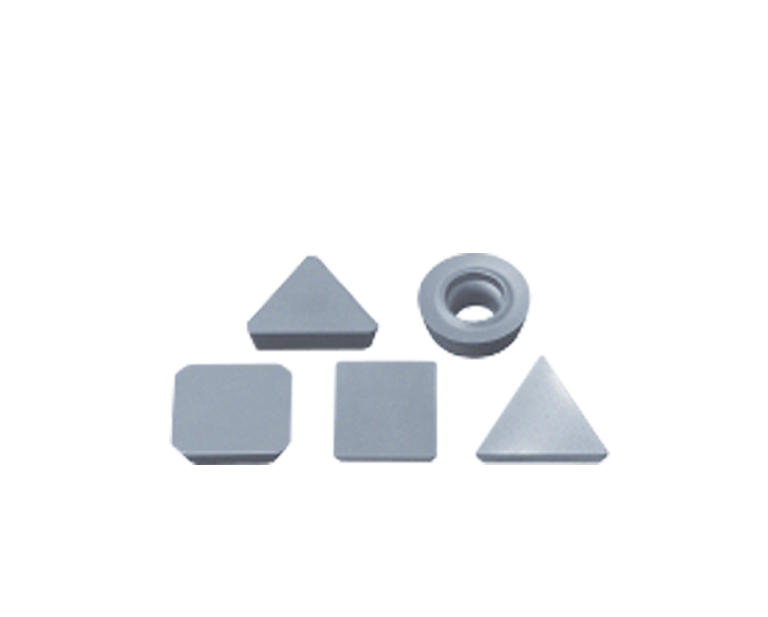

The tangential milling system now also includes system size 09. As the first step of the market launch, the new product portfolio includes a face milling cutter and an end milling cutter in a standard size and in XL with a longer shaft. The diameter range of the face milling cutter lies between 40 and 80mm, with two different tooth pitches. Face milling cutters are available in diameters from 20 to 32 mm. The tool system DELTAtec 90N Tang comes in four cutting grades right from the start. The grades BCP25M and BCP35M for the processing of steel, BCM40M for stainless materials and BCK20M for cast materials are available in the triedand-tested geometries and cutting edge finishes. In the second phase of the market launch, a helical milling cutter in a face and end milling version in the same diameter range will be added to the DELTAtec 90N Tang programme. As with the milling system in system size 13, a helical cutting edge will be used for soft cutting and the best possible distribution of cutting forces. Furthermore, great emphasis was placed on reducing vibrations through a specially developed, uneven spacing pattern.