No Product In Inquiry List

Characteristic

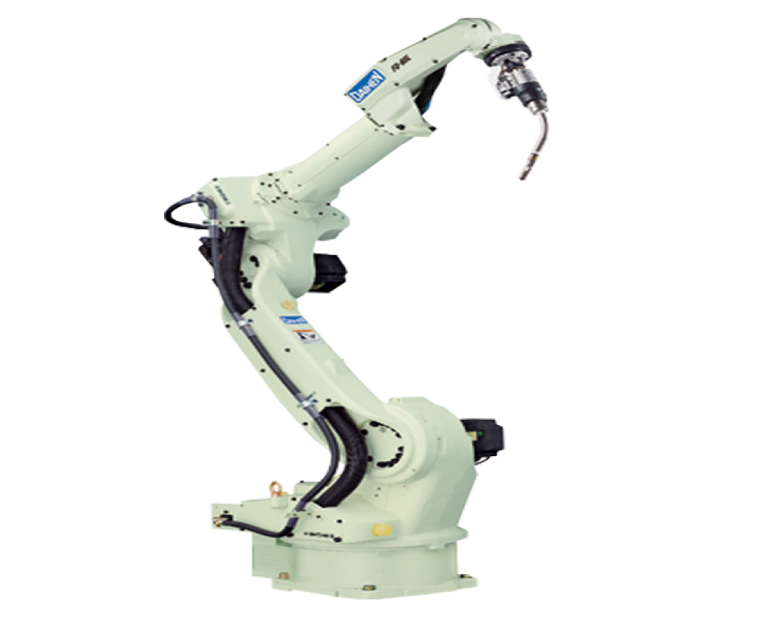

Microcomputer · thyristor controlled type CO 2 / MAG automatic welding machine

XD350 S-II

● Improved startability with high performance microcomputer

● Improved workability by unifying control cables

● Improved durability and robustness

Simple drip-proof seat on the front as standard, protecting panel parts from sudden rain during dust and outdoor storage!

● Consideration for the environment "Power saving circuit" "Fan stop function" "Gas saving function"

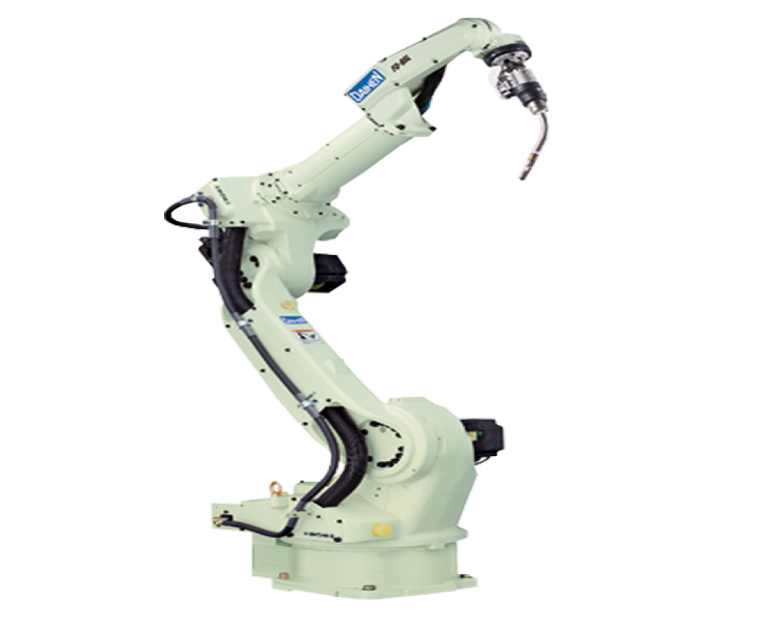

XD 500 S-II

- New high performance microcomputer is installed, the welding mode expansion and startability improvement are realized by the processing speed and the memory capacity up as much as the digital inverter welding machine!

● Resistant to input voltage / frequency fluctuations, always ensuring stable welding quality!. By installing "Brake Unit" sold separately on the feeder, it is possible to suppress the feed of wire at the end of the welding as much as possible! Effective for tack welding at extension!

● Improved robustness and maintenance system, such as standard equipped with a simple drip-proof sheet that protects panel operation parts!

Specification

|

Welding power supply |

CPXD-350 |

CPXD-500 |

|

Rated input |

3Phase 380/400V |

3Phase 380/400V |

|

Rated output |

350A/36V |

500A/45V |

|

Output adjustment range |

50~350A/15~36V |

50~500A/15~45V |

|

Rated usage rate |

50% |

60% |

|

Mass (dimension) |

103kg(372×690×659mm) |

164kg(454×701×859mm) |

|

Wire feeder |

CM-6202 |

CM-6202 |

|

Welding Torch |

BT3500-30、BT3510-30 |

BT3500-30, BT5000-30 |

|

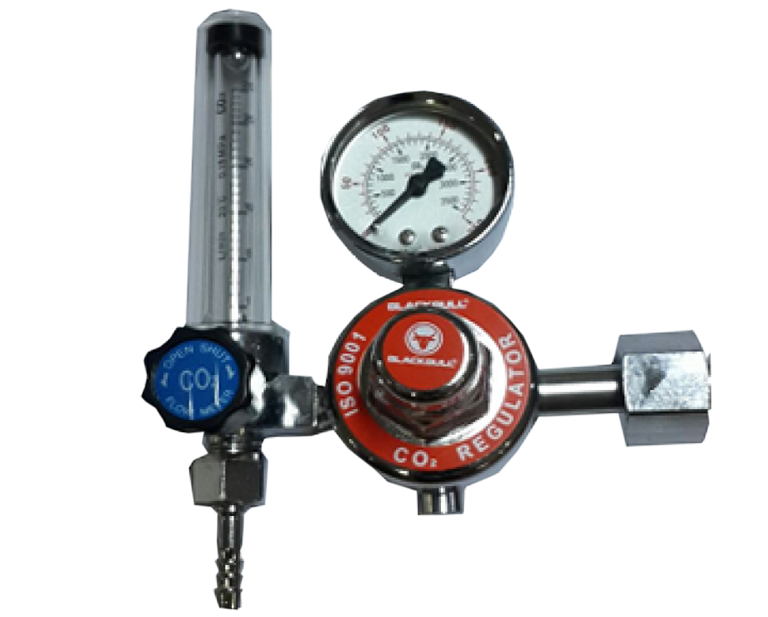

Gas Flow Regulator |

CO2:NP-201/MAG:D-BHN-2 |

FCR-226(With heater) |