No Product In Inquiry List

Served as both carbon dioxide and mixture gas, and stable arc performance in almost welding current

- Suitable for high speed welding of steel sheets by short circuiting transfer in all positions.

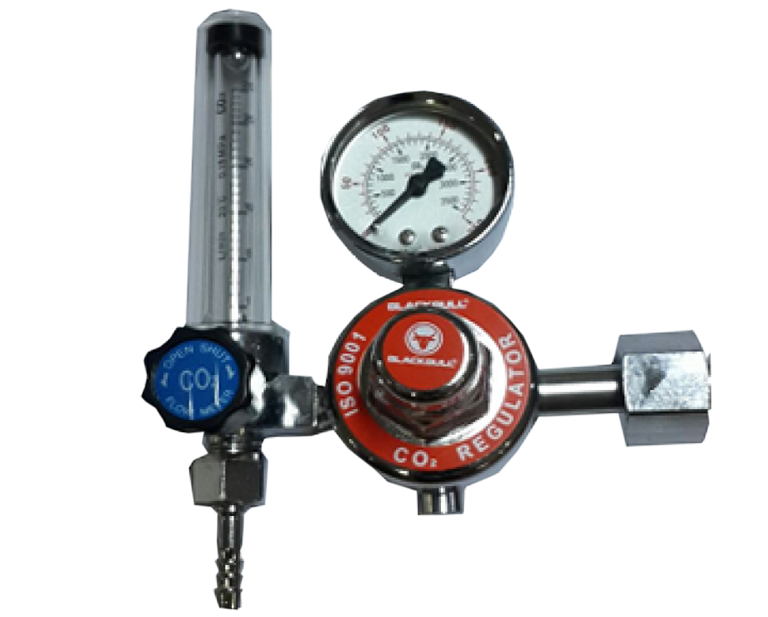

- Flow quantity of shielding gas should be 20?/min in general.

- Keep the distance between tip and base plate metal 6~15mm for 250 Amp. and under or within 15~25mm for more than 250 Amp. of welding current.

Typical chemical composition of wire (%)

|

Carbon |

Sulphur |

Silicon |

Manganese |

Phosphorus |

|

0,07 % |

0,007 % |

0,86 % |

1,53 % |

0,012 % |

KS : D 7025 : YGW12

AWS : A5.18 : ER70S-6

EN : 14341-A : G 42 2(3) C(M) G3Si1

EN : 14341-B : G 49A 3 C(M) G6

JIS : Z 3312 : YGW12

| Sizes (mm) | Standard | Welding Position View(+) |

Shielding gas | Polarity | |

|---|---|---|---|---|---|

| 0.8~1.6 | AWS A5.18 EN 14341-A EN 14341-B JIS Z 3312 KS D 7025 |

ER70S-6 G 42 2(3) C(M) G3Si1 G 49A 3 C(M) G6 YGW12 YGW12 |

F, HF | CO2 / Ar+20%CO2 | DC(+) |

| Typical chemical composition of wire (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | Remark |

| 0.07 | 0.86 | 1.53 | 0.012 | 0.007 | - | - | - | - |

| Typical mechanical properties of all-weld metal | |||||

|---|---|---|---|---|---|

| Y.S (MPa) | T.S (MPa) | EI. (%) | Hardness (HV) | IV (J) | PWHT |

| 450 480 |

550 580 |

30 28 |

- | 70 (-30℃) 80 (-30℃) |

- |